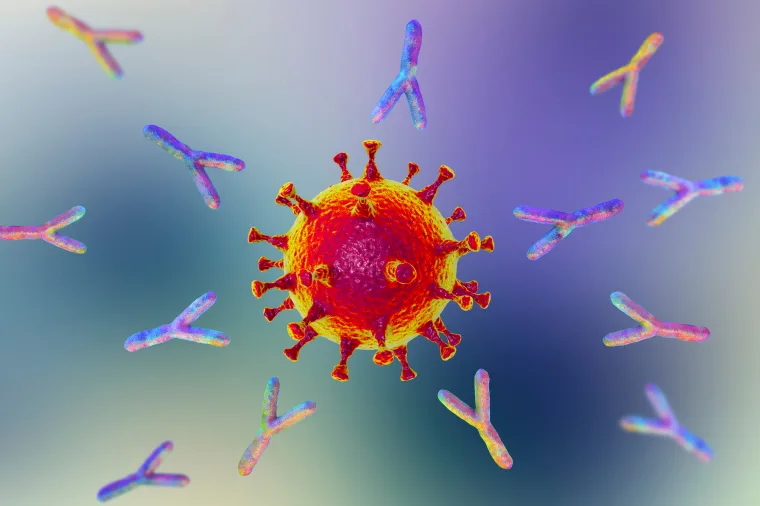

Antibodies are critical tools in research, diagnostics, and therapeutic applications. The production of high-quality, high-yield antibodies is a cornerstone of many biomedical and biotechnological advancements. Whether used for therapeutic treatments, research studies, or diagnostic assays, the efficiency and quality of antibody production are crucial for success. This article explores the different processes involved in antibody production, focusing on achieving high yield and ensuring quality results.

What is Antibody Production?

Antibody production refers to the process of generating large quantities of antibodies—proteins produced by the immune system to recognize and neutralize foreign molecules (antigens). There are two primary types of antibodies produced for research and clinical use:

- Polyclonal Antibodies (pAbs): A mixture of antibodies derived from different B cells that recognize different epitopes on an antigen.

- Monoclonal Antibodies (mAbs): Identical antibodies produced from a single B cell clone, all recognizing the same epitope on an antigen.

The choice between polyclonal and monoclonal antibodies depends on the application, with monoclonal antibodies being preferred for specific, reproducible results.

Key Steps in Antibody Production

The antibody production process involves several crucial stages, each contributing to the final yield and quality of the antibody. These stages include immunization, hybridoma generation, cell culture, and purification. Below is an overview of each step:

1. Immunization and Antigen Preparation

The first step in antibody production is the immunization of an animal (commonly mice, rabbits, or goats) with the target antigen. For monoclonal antibodies, this step involves preparing a purified version of the antigen to induce a robust immune response.

- Antigen Selection: The antigen must be carefully chosen to provoke an immune response. It is typically a protein, peptide, or a part of the pathogen of interest, such as an epitope.

- Adjuvant Use: To enhance the immune response, an adjuvant is often mixed with the antigen. Adjuvants stimulate the immune system to respond more vigorously to the foreign antigen.

2. Hybridoma Generation (For Monoclonal Antibodies)

For monoclonal antibody production, the process shifts to hybridoma technology. In this step, B cells (from the spleen of the immunized animal) are fused with immortalized myeloma cells, which are capable of dividing indefinitely. This creates hybrid cells—called hybridomas—that produce the desired antibody.

- Cell Fusion: The B cells from the immunized animal are fused with myeloma cells using a chemical or electrical method. This fusion creates hybrid cells that can replicate indefinitely and produce antibodies.

- Selection: After fusion, the cells are screened to select only those that are producing the desired antibody. This is done using a technique called HAT (hypoxanthine-aminopterin-thymidine) selection, which eliminates cells that do not fuse properly.

3. Screening and Cloning

Once hybridomas are produced, they must be screened to identify those that produce antibodies with the desired specificity and affinity.

- ELISA (Enzyme-Linked Immunosorbent Assay): A common method to test hybridomas for the production of antibodies specific to the target antigen.

- Flow Cytometry: This technique can be used to sort hybridomas based on their ability to bind to the target antigen.

- Cloning: After identifying the successful hybridomas, individual clones are selected and cultured to expand the antibody production.

4. Cell Culture and Antibody Production

Once the desired hybridomas are selected, they are cultured in large quantities to produce antibodies. There are two main systems for antibody production:

- In vivo (Animal Models): In this method, the hybridomas are injected into the peritoneal cavity of an animal, where they produce large quantities of antibodies that can be collected and purified.

- In vitro (Cell Culture): Hybridoma cells are cultured in bioreactors or flasks in controlled environments to produce antibodies. This method is often preferred for large-scale production and for producing humanized or fully human antibodies.

- Optimizing Yield: Factors like temperature, pH, and nutrient levels are carefully controlled to optimize the antibody yield. Additionally, the choice of culture medium is essential for achieving high productivity.

5. Purification of Antibodies

After the antibodies are produced, they must be purified to remove unwanted proteins, cellular debris, and other contaminants. There are several methods of antibody purification, including:

- Protein A/G Affinity Chromatography: This is the most common method used for purifying antibodies. It exploits the high affinity between immunoglobulins (IgG) and Protein A or G, which are immobilized on a column. The antibody binds to Protein A/G, while other proteins are washed away.

- Ion Exchange Chromatography: This method separates proteins based on their charge, allowing further refinement of the purified antibody.

- Size Exclusion Chromatography: This technique separates molecules based on their size and is often used as a final polishing step for high-purity antibodies.

The goal is to achieve high purity with minimal contaminants, ensuring the antibody’s effectiveness and safety for downstream applications.

6. Characterization and Quality Control

Once purified, the antibody must undergo extensive testing to ensure it meets the necessary quality standards. Characterization involves confirming the antibody’s specificity, affinity, and functionality.

- Western Blotting: Used to confirm the antibody’s ability to bind to the target antigen.

- Flow Cytometry: Assesses antibody binding and specificity in a cell-based environment.

- Binding Affinity Testing: Techniques like surface plasmon resonance (SPR) or enzyme-linked immunosorbent assays (ELISA) are used to measure how tightly the antibody binds to its target.

Additionally, functional assays are used to verify that the antibody can perform the desired biological function, such as neutralizing a pathogen or initiating an immune response.

Factors Affecting High-Yield Antibody Production

Several factors can influence the yield and quality of antibody production. These include:

- Host Selection: The choice of animal or cell line used for immunization and hybridoma generation can affect the immune response and antibody yield.

- Antigen Design: The antigen must be designed to evoke a strong immune response. This involves selecting an epitope that is immunogenic and easily recognized by the immune system.

- Cell Culture Optimization: Conditions such as temperature, pH, oxygen levels, and nutrient availability all impact the efficiency of hybridoma cell growth and antibody production.

- Purification Methods: Efficient and scalable purification methods ensure high yield and quality of the final antibody preparation.

- Scale-up Processes: For industrial-scale antibody production, optimizing the growth and culture of hybridomas or engineered cells in bioreactors is essential to achieve large quantities of antibody.

Applications of Antibody Production

Antibody production has a wide range of applications across various fields:

1. Therapeutic Applications

Monoclonal antibodies are widely used as treatments for a variety of conditions, including cancer, autoimmune diseases, and infectious diseases. They are designed to specifically target disease-causing agents or pathways.

2. Diagnostic Tools

Antibodies are commonly used in diagnostic assays such as ELISA, immunohistochemistry, and Western blotting. These techniques help detect biomarkers for diseases, including cancer, infections, and autoimmune conditions.

3. Research and Biotechnology

In research, antibodies are used to study specific proteins, cell signaling pathways, and gene expression. They also play a key role in techniques such as immunoprecipitation, immunofluorescence, and flow cytometry.

4. Vaccine Development

Antibodies are critical in the development of vaccines, especially monoclonal antibodies that can target specific pathogens. These antibodies can be used as immunotherapy or serve as a model for designing vaccines.

Conclusion

The production of antibodies—whether polyclonal or monoclonal—requires a multi-step process that includes immunization, hybridoma generation, culture, purification, and extensive quality control. The success of antibody production hinges on optimizing each of these steps to achieve high yield and quality. With advances in biotechnology, antibody production continues to play an essential role in research, diagnostics, and therapeutic applications, providing valuable solutions for various medical and scientific challenges.